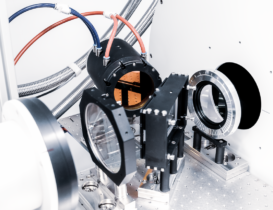

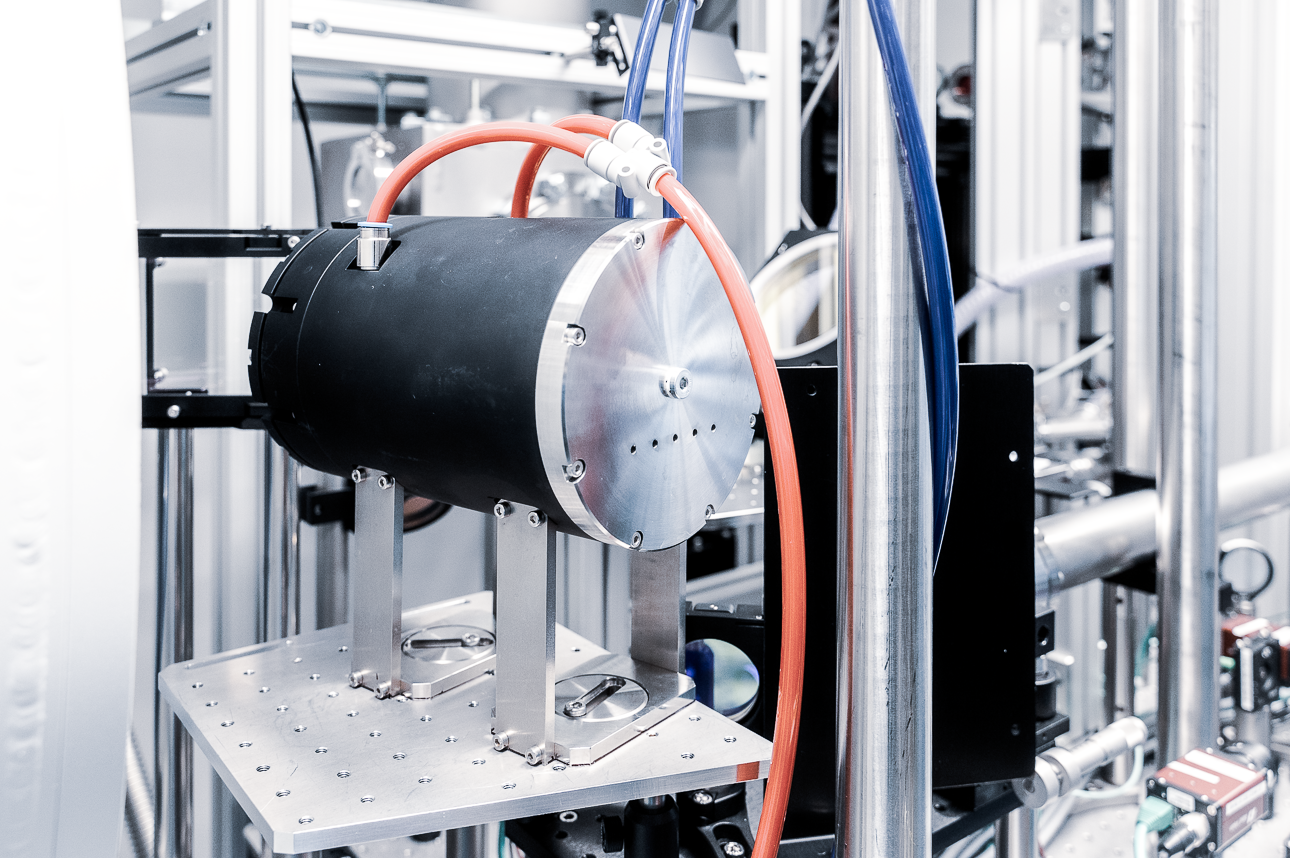

Helena Picmausová and her colleagues Pavel Crha, Karolina Macúchová, Jan Heřmánek and Martina Řeháková have managed to significantly improve the beam absorber we use for the BIVOJ laser system. It is one of the high-performance laser systems and holds several records in its class. It has consistently achieved an energy of 145 J in a 10 ns pulse at a repetition rate of 10 Hz at a wavelength of 1030 nm, which has not been achieved by any other laser in the world. An efficient and safe beam absorber is therefore a necessary component of such high-power laser systems, which operate above the destruction threshold of most conventional optical elements. Its purpose, as its name implies, is to safely absorb the energy of the photons that make up the laser beam.

The optimization was performed by our colleagues using numerical simulations in the SOLIDWORKS Flow Simulation module environment, based on the finite volume method with a structured computational mesh. The absorber design was optimized in two steps with emphasis on appropriate flow field characteristics for efficient removal of thermal energy from the system. The goal was to achieve a high degree of turbulence, vorticity and heat flux, along with minimizing pressure and velocity losses in the flow and maintaining the manufacturability of the assembly components.

While the original design allowed only 540 W of the total 1500 W to be dissipated using cooling water, the final design dissipates 1340 W using cooling medium.