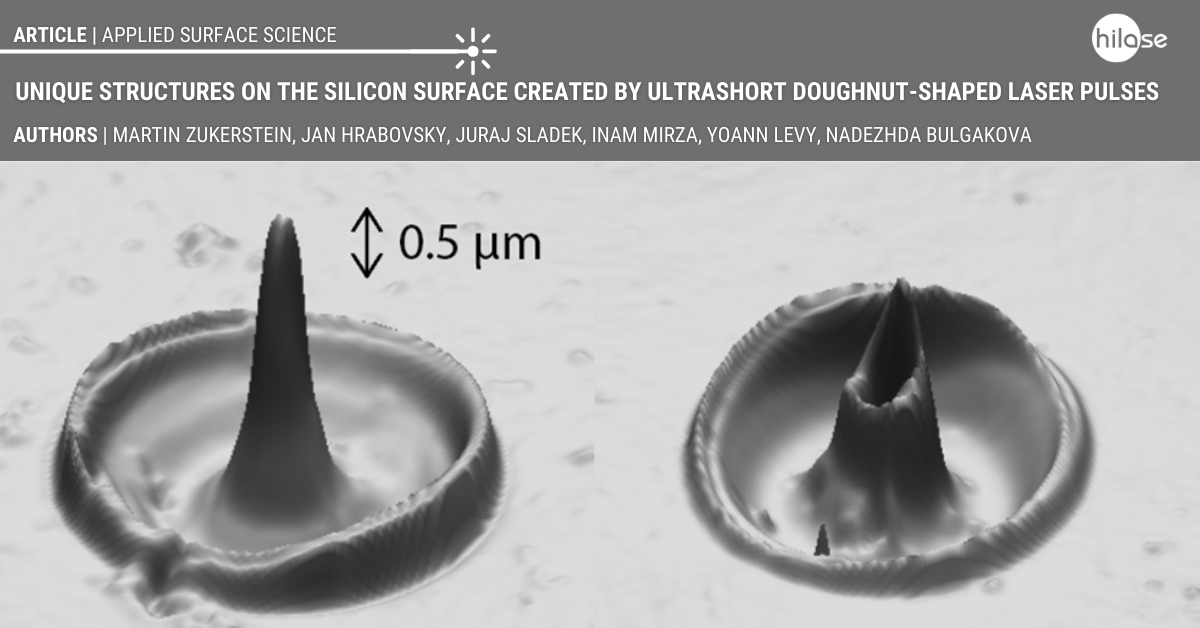

A team of scientists from the HiLASE Centre, Martin Zukerstein, Jan Hrabovsky, Juraj Sladek, Inam Mirza, Yoann Levy and Nadezhda Bulgakova, introduced a smart technique for the formation of unique structures on a silicon surface by a laser. Specially shaped laser pulses with a very short duration were used to create needle-like protrusions with a hollow core (see image).

The mechanism of formation of the needle structures can be explained as follows. The doughnut-shaped intensity profile of the laser pulse initiates ring-shaped melting of the material followed by an ablation within the molten area. Due to recoil pressure of the ablation plume, the melt is pushed both towards the periphery and towards the central unmolten region, thus forming the rims at outer and inner boundaries of the molten zone. Thanks to material relocation geometry, the inner rim represents a tubular structure and, at an optimal pulse energy, this structure closes at its top. At single laser pulses, the height of needles is limited to ca. 0.5 micrometers but can be increased by multi-pulsed irradiation.

The discovered needle formation is highly reproducible and can find applications in various scientific fields, such as intracellular drug delivery, micro/electromechanical systems, and silicon-based photovoltaic and photonic devices.

A paper on this topic have been published in the prestigious international journal Applied Surface Science (IF = 6.707) devoted to applied physics and chemistry of surfaces and interfaces.