Laser micromachining (cutting small micrometre size holes, precise cutting and surface structuring) can improve and create new functionalities of products, thus adding more value and significantly increasing their market advantage. Eco-friendly laser micromachining processes can simplify and reduce production complexity and increase efficiency by eliminating the usage of chemicals and coatings.

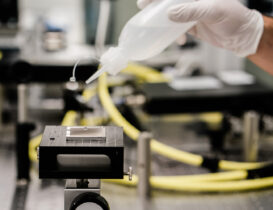

The HiLASE Centre R&D team can design proof of concept and develop application processes for laser micromachining. Using unique PERLA® lasers and modern multi-beam processing equipment, the HiLASE Centre can design processes that are order of magnitude faster and more efficient than current industrial processes.

Tooling

Tooling

Flat-panel display

Flat-panel display

Benefits of LMM

- Drilling of small µm size holes with low thermal damage

- Cutting sensitive and difficult to process materials with low thermal damage

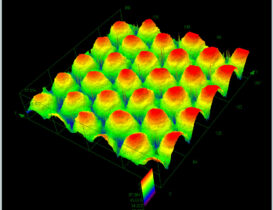

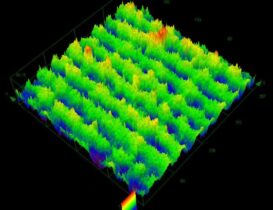

- Creating of nm to µm sized surface structures for needed function

- Can be applied to metals and alloys | glass and dielectrics | polymers | composite materials

40401

simultaneous beams - world record

180°

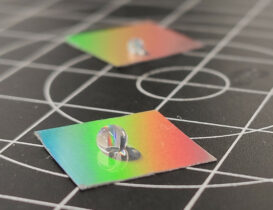

max. SCA of super-hydrophobicity

98%

reduced bacteria growth

1000 cm2/min

productivity of surface structuring

Why work with us

- Design of processes that are order of magnitude faster and more efficient than current industrial practices

- Extensive R&D capabilities to design proof of concept and develop application processes

- Experienced laser design team to customise the laser system for specific applications

- Benefit of our international network of academia and industrial partners

- Unique PERLA® laser systems

- Modern multi-beam processing equipment

- Reliable product support in cooperation with our industrial partners

- We provide a wide range of services from the evaluation of customers‘problem, through proposing suitable structure, creating and testing sample surfaces, process development and optimisation, to consulting and support during process implementation.

HiLASE Centre Equipment & Services

| Scanners | |

|---|---|

| ScanLab | IR and VIS; speed > 2 m/s; F-theta lenses from 70 to 163mm; spot sizes 15 – 50 µm |

| PULSAR | IR: 1030nm; speed > 2m/s; combined with beamshaping and beamsplitting unit |

| In-house development DLIP setup | IR and VIS; adjustable interference pattern 2 – 30 µm (lines or dots) |

| Multi-beam scanners | IR and VIS; speed > 2m/s; compatible with DOE beamsplitters for up to 2601 sub-beams |

| Stages | |

|---|---|

| Aerotech | Working area 150x100mm; accuracy < 1µm; repeatability < 0.5µm; speed up to 0.1m/s |

| Standa | Working area 600x600mm; accuracy < 5µm; repeatability < 1µm; speed up to 2m/s; acceleration up to 3g |

| Post process characterization |

|---|

| Confocal microscope |

| SEM |

| Contact angle measuring device |

| AFM, Raman |

Contact us

Ready to explore the potential of laser micromachining or just need to know more? Please contact us here or at solutions(at)hilase.cz, and we can start creating your solution together.