Reliability of high-power lasers is to a large extend given by optical components used in them. Therefore, the knowledge of the quality of used components is essential for safe and reliable operation of laser systems. The LIDT (Laser Induced Damage Threshold) value indicates the maximum amount of optical energy (power) that component can withstand before damage occurs.

The HiLASE Centre offers LIDT services, thanks to unique laser sources (such as BIVOJ laser, 10J, 10ns, 10 Hz) under a unique regime with big top-hat spot and high energy. A number of LIDT procedures is available, based on ISO standard 21254 series or customized according to specific needs. We have established a Quality Management System in our LIDT laboratory and received the ISO 9001 CERTIFICATE.

Optics

Optics

Laser R&D

Laser R&D

Laser Machine Integrators

Laser Machine Integrators

Laser End-users

Laser End-users

Benefits of LIDT

- Tests accurate damage threshold limits of various optical components and materials.

- Supports the development of high-power optical components .

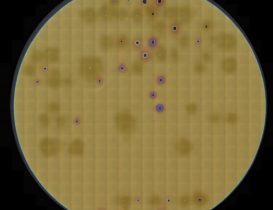

- Identifies production defects of optical elements.

- Tests large size optical element.

- Provides processing window values for laser material processing.

- Can be used for testing of dielectric materials, amorphous or crystalline | metals | ceramics | various exotic compounds and alloys.

1.5 kg

available weight of samples

1030/515/343 nm

wavelengths

15 mm

max. spot size Gaussian beam

Why work with us

- Extensive R&D capabilities to develop and apply LIDT testing

- State-of-the-art pulsed laser systems with unprecedented intensities

- Capability to perform LIDT at truly edge conditions

- ISO class 7 clean laboratory allows measurements with unbeatable precisions

- ISO-certified or custom-designed tests with results delivered on ISO-compliant protocols

HiLASE Centre Equipment & Services

| Picosecond pulsed laser | @1030 nm, <1.8 ps, 1 kHz rep. rate, up to 100 mJ energy in pulse |

| Nanosecond pulsed laser (Bivoj) | 1030 nm, 10 ns, 10 Hz rep. rate, up to 10 J energy in pulse |

| Experimental chamber | Testing at vacuum down to 10-3 mBar or in the presence of non-corrosive gas pressured up to 1.4 Bar |

| Sample surface area | Up to 100 x 100 mm2 |

| Spot size range | From 0.4 mm to 15 mm |

| Available weight of samples | Up to 1.5 kg |

| Beams | Up to 15 mm spot diameter round Gaussian or 3x3 mm2 square top-hat beam |

| Wavelength | 1030 / 515 / 343 nm |

| Pulse duration | 10 ns / 1.8 ps |

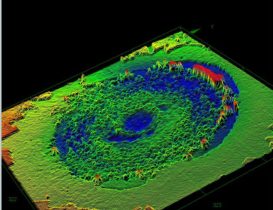

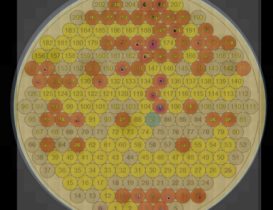

| Advanced on-site and ex-post samples monitoring and analysis | 1k fps 1.3 Mpix camera, beam profilers, confocal microscope |

| Types of measurement | ISO-standardized 1-on-1 and S-on-1 or custom raster-scan and ramp |

| Samples mounting | High-precision vacuum-compatible motorised micrometric stages with cryo-cooled sample holder |

"We have worked with the HiLASE Centre LIDT testing facility for a long time. The co-operation has allowed us to develop optics that meet the highest LIDT requirements and we very much appreciate the quick and efficient service that the HiLASE Centre LIDT testing facility provides."

Contact us

Ready to explore the potential of LIDT or just need to know more? Please contact us here or at solutions(at)hilase.cz, and we can start creating your solution together.