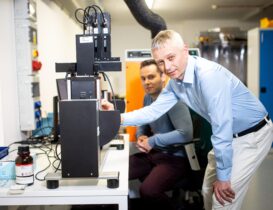

The Werner von Siemens Award for the first place in the Best Dissertation category was awarded to Ing. Petr Hauschwitz, Ph.D., leader of the LMM team of the HiLASE Centre, which is part of the Institute of Physics of CAS.

The Werner von Siemens Award is awarded to the best students, teachers and young scientists by the Czech branch of Siemens. Together with the students, the supervisors and mentors of their work are also awarded. Petr’s supervisor was none other than Ing. Tomáš Mocek, Ph.D., head of the HiLASE Centre.

This was the twenty-fourth installment of the competition and the expert jury selected from 568 applications. 900 thousand CZK were distributed among the 21 winners. The Czech Academy of Science won 4 awards in the following categories: Most Outstanding Fundamental Research Result, Award for Excellence in Women’s Scholarship and Best Dissertation (1st and 2nd place).

AWARD-WINNING DISSERTATION

Title of dissertation: “Large-Scale Functionalization of Surfaces Using Laser-Generated Micro- and Nanostructures” | Czech Technical University – Faculty of Nuclear and Physical Engineering

We asked Petr several questions regarding his award-winning dissertation.

You won first place in the Werner von Siemens Award 2021 in the Best Dissertation category. Could you please describe, in simple terms for the non-expert public, what you did in your dissertation and what was the result of your research?

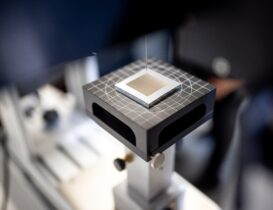

“In my work, I have focused on the development and fabrication of functional surfaces using laser-created micro and nanostructures. Such structures can change the surface properties of materials (wettability, friction, adhesion, biocompatibility, etc.). Beyond the surface structure itself, I have also been looking at how to bring this scientific discipline into the real world. In fact, the production of these surfaces is very slow and thus expensive. Therefore, the main part of my work is devoted to technology that makes it possible to parallelize the production of such processes. This is the so-called multibeam machining, where instead of one input laser beam we use tens of thousands of beams simultaneously, thus speeding up the production of functional surfaces by an order of magnitude, which makes it economically interesting for industry, not only for science.”

PETR AND WORLD RECORDS IN NANOSTRACTURING

The combination of processes and techniques used or developed as part of his PhD thesis has made it possible to set two world records in 2021 – for the speed of nanostructuring on stainless steel and for the number of laser beams simultaneously machining the material.

- 40 401 beams is a new record in laser multi-beam nanostructuring | PRESS RELEASE

- HiLASE Centre scientists have broken the world record in the speed production of laser-induced periodic nanostructures on a stainless steel surface | PRESS RELEASE

“By combining the unique PERLA laser system developed at HiLASE with a new prototype diffractive optical element developed by the Israeli hi-tech company HOLO/OR, parallel nanostructuring using more than 40,000 laser beams has been demonstrated, with a nanostructuring productivity of over 1,900 cm2/min. This makes the industrial adaptation of laser nanostructuring on a larger scale a realistic and innovative method for the rapid and economical production of, for example, superhydrophobic surfaces,” says Tomáš Mocek about Peter’s success.

PRACTICAL APPLICATIONS

“Application of the new surface treatment method is possible, for example, in the creation of antibacterial surfaces in medicine, surfaces for cell growth on body implants, friction-reducing surfaces for machine tools, self-cleaning surfaces, or anti-reflective surfaces. In a number of cases, the results of my work are already in practice or very close to it – for example, in the creation of functional surfaces that improve friction and lubricant efficiency in a German steel plant, or in the production of new types of batteries,” Petr explains.

PETR AND THE WERNER VON SIEMENS AWARD

What does the award mean to you personally and would you recommend participation in this or any other competition to other young or aspiring scientists?

“The Werner von Siemens Award is one of the most prestigious awards in the Czech Republic and I appreciate it very much. It is an honor for me and a motivation for the future because, like many other things, it confirms that the technologies I am involved in have a great purpose and potential for the future. I applied at the suggestion of my supervisor, Tomáš Mocek, and I would like to thank him once again. I would advise young scientists to not be afraid to assert themselves and go to the market, for example by participating in these competitions. Often, their work is of higher quality than they think.”

PETR AND THE FUTURE

You’re a young, successful scientist, team leader, a fairly popular figure in the scientific community, you’ve achieved several world records, 30under30 – where do you see yourself in 5 years? Where is your career path heading?

“Considering how well our micromachining group is taking off, I see a very promising future in 5 years. In general, our goal is to transfer knowledge and know-how to the Czech industry and thus increase the competitiveness of Czech companies. Our long-term vision is thus to find a key application and partner for the technologies we have developed, for example with the potential for future spin-offs. I think that within 5 years, the first such spin-off using the know-how of the micromachining group could be here.

In addition, I am considering more active involvement at the Faculty of Nuclear and Physical Engineering and student leadership. I currently have 2 PhD students and one graduate student and would be happy if they could achieve similar success.

What else? If they have a spot in #Hydepark I’d love to chat with @Danijel Stach. Maybe my recent successes will convince the editors ?.”

YOU CAN READ THE FULL PRESS RELEASE FROM SIEMENS HERE.