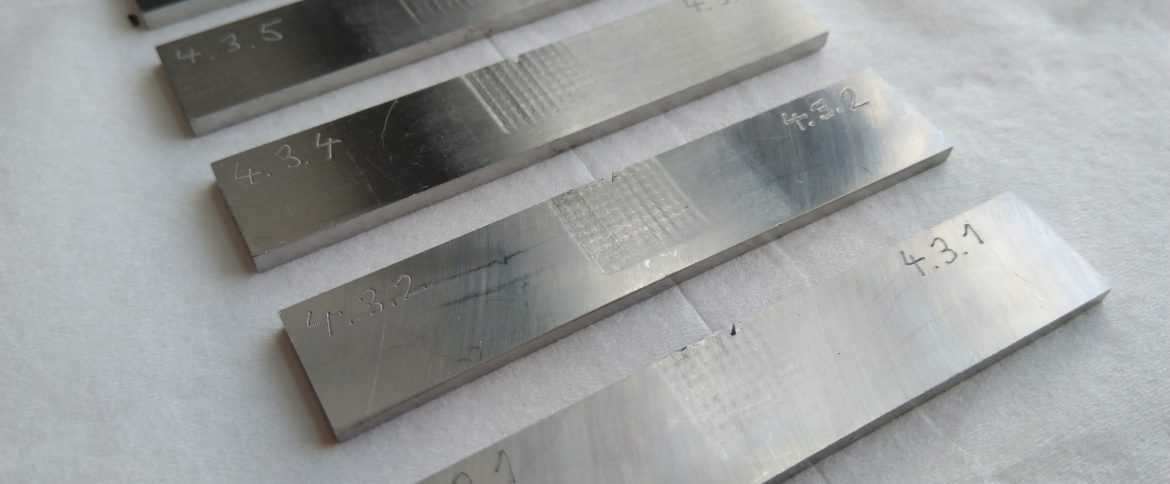

The application team of the HiLASE Centre has successfully applied the Laser shock peening technique on Austenitic steel 08CH18N10T which is used for construction of nuclear reactor vessels. This steel alloys is susceptible to SCC (Stress Corrosion Cracking) which is a phenomena where the part fails (cracks) under the combined influence of aggressive environment, weakened material and tensile stresses introduced during manufacturing. After the treatment, the samples were subjected to 3-point bend fatigue test. Due to the newly introduced residual stresses, the high cycle fatigue performance of the alloy after the treatment was improved over the whole range of loading stresses, ranging from 17% improvement for the highest loading stress up to 66% improvement for the lowest loading stress. Here you can find more success stories of the HiLASE Centre.