The first year of the HiLASE Laser Induced Damage Threshold Challenge has its winner! In this competition, we have tested ten samples of high reflective dielectric coated mirrors at the HiLASE Centre ISO certified LIDT laboratory. Of all the components tested, the Laseroptik sample with a value of 0.4 J/cm2 performed the best. A representative of Laseroptik received the award on Wednesday 27 April during a ceremony at the Laser World of Photonics in Munich.

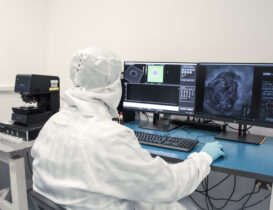

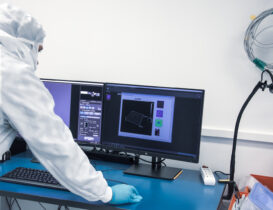

Samples of 2-inch diameter mirrors were tested with 1-ps pulses at wavelength 343 nm, round, Gaussian beam with 1 mm diameter in the plane of incidence. Tests were conducted in a clean room at ambient pressure and temperature, angle of incidence was 0° and target pulse-count reached 100 000. The testing was carried out using Olympus‘ LEXT 5100, which provides 2D and 3D image capture, HDR contrast, 4K resolution, profile measurement and surface roughness measurement, among other features.

At the HiLASE Centre, we provide state-of-the-art testing of materials and components on resistance to laser irradiation at controlled conditions. A number of LIDT procedures is available, based on ISO standard 21254 series or customized according to specific needs. We have established a Quality Management System for materials testing on Laser Induced Damage Threshold and our LIDT laboratory has received the ISO 9001 CERTIFICATE. Please contact us at solutions@hilase.cz to learn more.