On Tuesday, April 22, 2025, experts, technicians, and laser technology enthusiasts gathered at the HiLASE Centre to take part in an intensive, hands-on Laser Maintenance course organized by our Laser Training Centre (LTC).

Over a single day, participants immersed themselves in three key areas – measuring, aligning, and cleaning laser systems. The course was designed to offer not only a solid theoretical foundation but above all, practical skills that can be immediately applied in real-world operations.

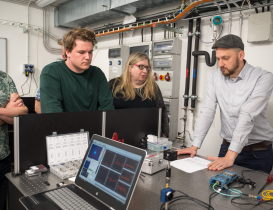

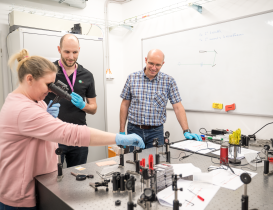

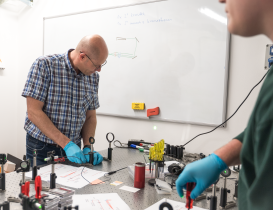

Measuring the Output Parameters of a Laser

The first part of the course was led by Jan Pilař and Ondřej Denk, who guided participants through the fundamental parameters of a laser beam. Together, they focused on measuring beam diameter and collimation, power, pulse energy, and the laser radiation spectrum.

They also explained the importance of commonly used indicators such as M², Strehl ratio, and Beam Parameter Product (BPP). Participants had the opportunity to try everything hands-on — and this very opportunity to “get their hands on it” was often mentioned as the highlight of the entire block.

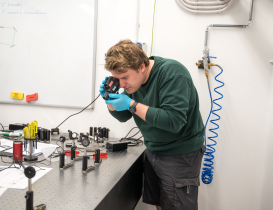

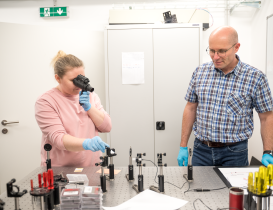

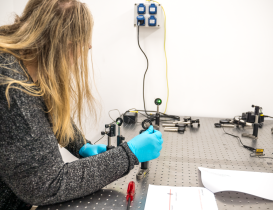

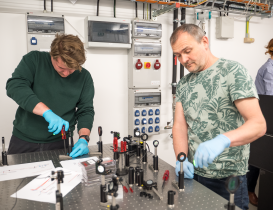

Laser Beam Alignment

In the second part of the training, Jan Kaufman and Dominika Jochcová took the lead, guiding participants through the principles of safe laser beam handling.

During the practical session, participants had the chance to align and collimate both visible and invisible (infrared) beams to a reference point, build an optical telescope, and understand its function within the laser system. The session also included hands-on work with optomechanical components, with a strong emphasis on precision, safety, and efficiency during alignment procedures.

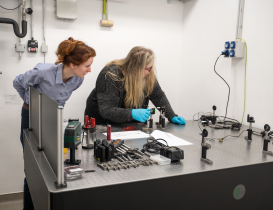

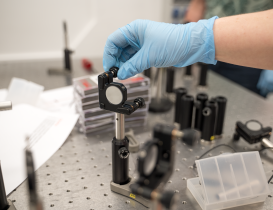

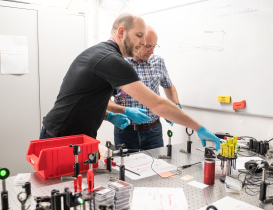

Cleaning Optical Components

The final technical block was led by Martina Řeháková, Vitalii Uvarov and Martin Hanuš, who introduced participants to proper methods for cleaning optics, selecting appropriate materials and tools, and identifying when an optical surface is truly clean.

Participants observed real-life demonstrations of cleaning various optical components. The session also addressed specific cases, such as the care of optical gratings and fibers, as well as the importance of working in a clean environment.

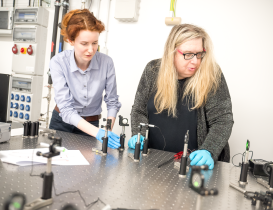

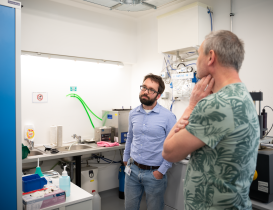

A Course Full of Practical Skills

The atmosphere throughout the day was friendly and inspiring. There was plenty of opportunity to discuss real operational challenges from participants’ workplaces, as well as time for individual questions and experience sharing.

We thank all participants for their energy, curiosity, and excellent cooperation.

Interested in HiLASE LTC training courses?

Take a look at our current offering of courses and events: https://www.hilase.cz/en/events/