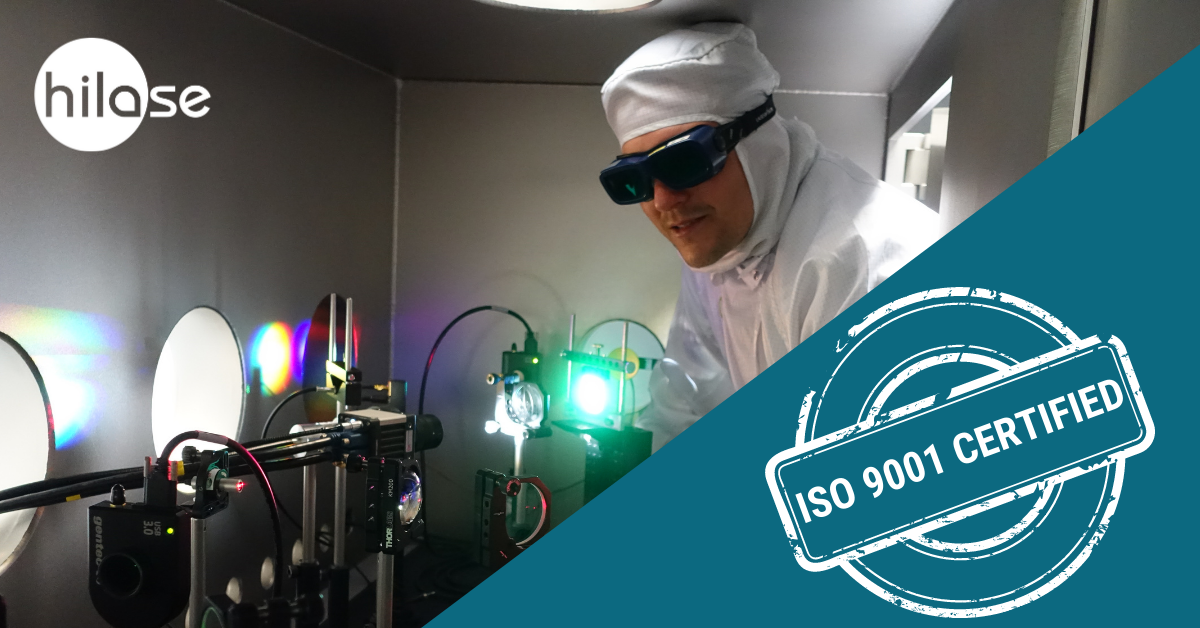

In the HiLASE Centre we strive to deliver high quality products and services to our customers. Therefore, we have established a Quality Management System for materials testing on Laser Induced Damage Threshold. Our LIDT laboratory has received the ISO 9001 CERTIFICATE (valid until March 2024).

The LIDT technology enables testing of materials and components on resistance to laser irradiation at controlled conditions. We provide top-class service in LIDT testing covering both ISO-compliant damage measurements and laser processing window assessment. Our new LIDT laboratory setup allows LIDT testing using round Gaussian beam and top hat beam 3×3 mm2 size. As a result, we are able to provide customized damage threshold tests particularly suitable for energy handling assessment. Furthermore, systems for wavelength conversion were installed providing 343 nm and 515 respective wavelengths along with 1030 nm fundamental for testing. Together with established large vacuum testing chamber, micrometric motorized sample mount and precise beam diagnostics it offers exceptional tool for laser damage assessment.

Thanks to our long-term experience we help to both laser system users and developers, helping them to identify and improve the quality of the components. See more about our services in this handout.