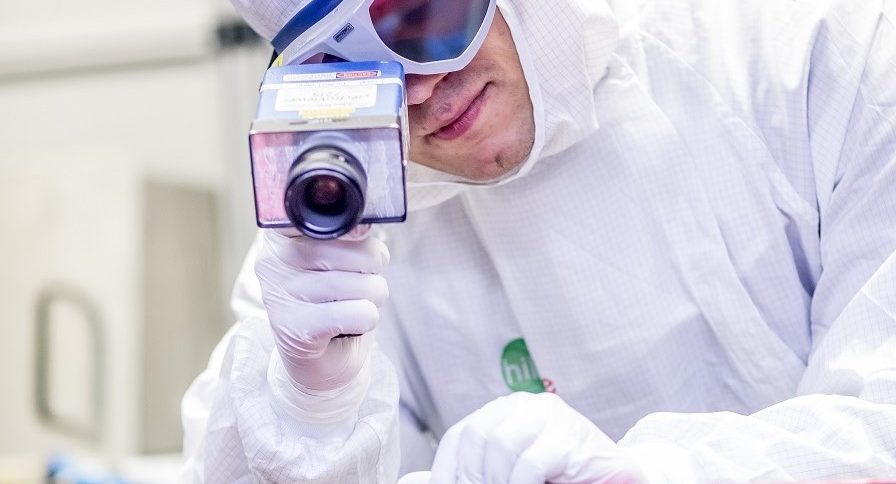

Listen to an interview with Petr Hauschwitz, team leader of Laser Micromachining (LMM) at the HiLASE Centre, broadcasted by Czech Radio. In a conversation with reporter Eva Kézrová, he shared what his team is working on within biomedical applications. He explained how antibacterial surfaces are made using LMM, and what are the goals of their future research.

They discussed a sample made from stainless steel, treated with Laser Micromachining with the goal of creating an antibacterial surface. Even though the material appears smooth to the touch, there is an extremely fine microstructure on it, reducing bacterial adhesion.

Petr Hauschwitz describes, how the nanostructure works: “The structure is smaller than the average size of the bacteria being studied,” he explains. “That means the bacteria does not attach, does not start to form colonies and can be easily removed from the surface.”

He highlights that, even though it may be possible to describe the process so simply, in practice, they have to take many different factors into account. “Different bacteria have different sizes, so the structures have to reflect that. Of course, some of the most insidious bacteria we want to defend against are E-coli or Staphylococcus… but there are many different types of bacteria and microorganisms,” he describes. “We want to go deeper and ideally develop a surface that will prevent a broad spectrum of microorganisms from attaching.”

This laser micromachining application is one of the topics of the LasApp project, within which the HiLASE Centre collaborates with BIOCEV (a research centre of the Faculty of Science of Charles University). Together, they have the goal of increasing the availability of surfaces which prevent biofilm formation for medical and industrial applications. In the interview, Petr Hauschwitz describes one of their research endeavours: “One of our goals for the LasApp project is to transfer the negative of a laser-induced mould onto a plastic part in the classic mass production injection moulding process, making the whole thing cheaper, faster, and more accessible to industry.”

The development of this unique laser application is made possible in large part by the cutting-edge laser technology developed by HiLASE Centre scientists. The PERLA laser system used by Petr Hauschwitz’s team in their experiments holds two world records: