Essential part in the development of new generation high intensity lasers and their industrially reliable application is determination of Laser Induced Damage Threshold (LIDT) of newly designed optical components and their coatings. Our goal is development of a methodology for LIDT measurements under those new laser radiation regimes in order to contribute in understanding a very complex mechanism of damage occurrence. We are developing LIDT dedicated experimental facilities which will be suitable for ISO LIDT test 1-on-1, s-on-1 type1 and 2, and r-on-1 under ns and ps pulses with laser wavelengths from UV to MIR (at the moment only at 1030nm) . Station is designed to accept samples up to 1.5 kg heavy with dimensions up to 100mm x 100mm x 100 mm. LIDT measurements can be done with variable spot size and with incidence laser beam angle between 0° to 60°.

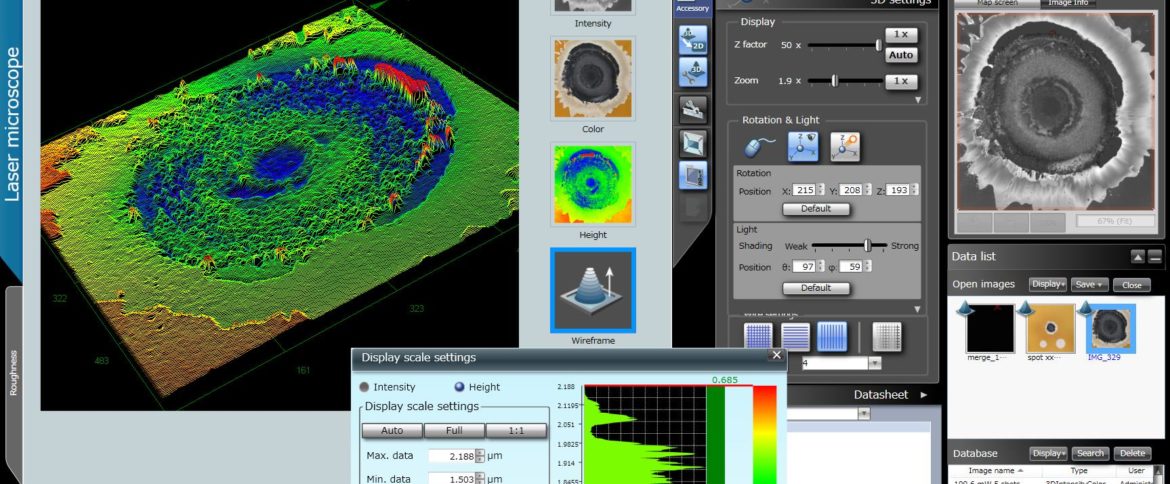

For in-situ damage observation we use two methods: scattered light monitoring and online fast camera microscopy. Such detection allows accurate determination of damage occurrence as well as continuous monitoring of exposed sample surface and evaluation of damage precursors. For post-mortem characterization we do use laser scanning confocal microscope to observe damage morphology. We are able to reconstruct 3D image of any crater or breach on the surface with lateral resolution of ~100 nm and z-resolution ~1 nm.

Team members: Dr. J. Vanda (Team Leader), Dr. M.- G. Muresan, Dr. S. Pakalnis, M. Mydlář, K.Pilná.

More details about our LIDT services are available here.